+86-173-0318-1768

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-23 Origin: Site

Are you aware of the critical role flotation impellers play in mining? These components are essential for effective mineral processing and separation.

In this article, we’ll explore the top three flotation impellers used in the industry. You’ll learn about their design, functionality, and how they enhance mining efficiency.

Flotation impellers are crucial components in the mining industry, designed to enhance mineral processing. Their unique features significantly impact operational efficiency and overall performance.

Flotation impellers come in various designs, each tailored for specific mining applications. The materials used in their construction play a vital role in their effectiveness. Common materials include:

● Rubber: Known for its excellent wear resistance and flexibility, rubber impellers are ideal for moderate abrasion conditions.

● Polyurethane: This material offers superior chemical stability, making it suitable for corrosive environments.

● Stainless Steel: Often used in laboratory settings, stainless steel impellers provide durability but are less common in standard mining applications.

One standout feature found in some high-quality models, like those from Strudex, is the embedded metal skeleton. This design enhances structural strength, allowing the impeller to withstand harsh mining conditions. The integration of a metal skeleton not only improves durability but also extends the service life of the impeller, reducing the frequency of replacements.

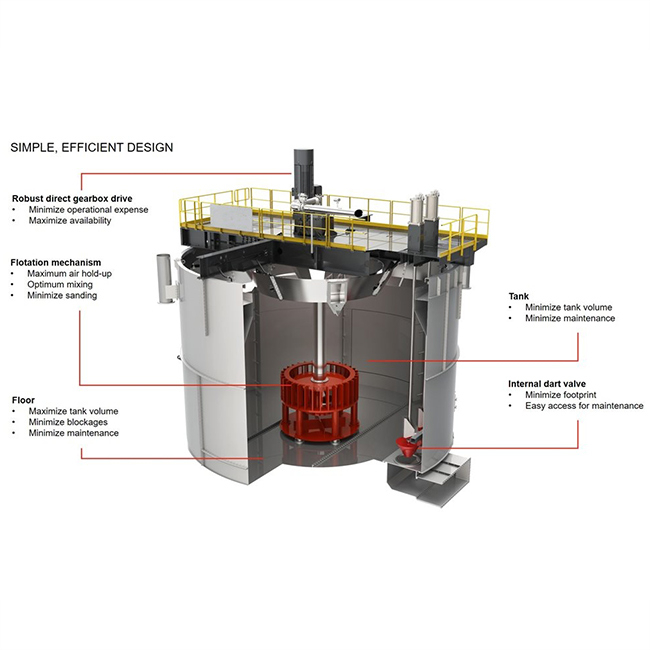

The design of a flotation impeller directly affects how well it performs in mixing slurry and aerating it. An effective impeller ensures optimal slurry movement, which is critical for efficient mineral separation. Here are some key aspects:

● Slurry Mixing: A well-designed impeller creates turbulence in the slurry, promoting better mixing. This is essential for maximizing contact between air bubbles and minerals.

● Aeration: Efficient aeration leads to improved air hold-up, which is vital for effective flotation. The right impeller design can significantly enhance the aeration process.

The impact of flotation impellers on mineral recovery rates cannot be overstated. A high-performance impeller can lead to improved concentrate recovery, translating to higher efficiency in mining operations.

Impeller Type | Material | Durability | Aeration Efficiency | Recommended Use |

Strudex Rubber Impeller | Rubber | High | Excellent | Moderate abrasion ores |

Strudex Polyurethane | Polyurethane | Superior | Very High | Corrosive slurries |

Standard Stainless Steel | Stainless Steel | Moderate | Low | Laboratory settings |

In summary, the key features of flotation impellers, including their design, materials, and operational efficiency, play a significant role in enhancing mining productivity. Choosing the right impeller can make a substantial difference in the effectiveness of mineral processing operations.

Flotation impellers are essential for optimizing mineral processing in mining. Here, we explore the top three types of flotation impellers, highlighting their unique features and applications.

Receded disk impellers are widely recognized for their innovative design. These impellers feature a recessed shape that allows for higher rotation speeds without increasing horsepower. This design not only enhances aeration but also improves froth stability, which is crucial for effective mineral separation.

Key Advantages:

● Aeration Efficiency: The recessed design facilitates better air bubble distribution, leading to improved flotation performance.

● Froth Stability: A stable froth column is achieved, allowing for higher recovery rates during the flotation process.

Best Applications: Receded disk impellers are ideal for applications requiring high recovery rates and fine bubble generation. They excel in various mining environments, particularly in the processing of sulfide ores.

Brand Highlight: Leading manufacturers like Metso Outotec have effectively utilized this design in their flotation equipment, enhancing overall operational efficiency in mining operations.

Conical disk impellers are another popular choice in the mining industry. They feature a traditional design with backward-inclined blades, which can vary from single-layer to multi-layer configurations. These impellers are designed to balance slurry agitation and air dispersion effectively.

Key Advantages:

● Balanced Performance: The unique blade design allows for optimal mixing of slurry and effective air distribution.

● Versatility: They are suitable for a wide range of flotation applications, making them a flexible choice for many mining operations.

Ideal Use Cases: Conical disk impellers are commonly used in general-purpose flotation machines, including those in the SF and XJK series. Their ability to adapt to different conditions makes them a favorite among operators.

Brand Highlight: FLSmidth has made significant innovations in conical disk impeller technology, improving their performance and reliability in various mining scenarios.

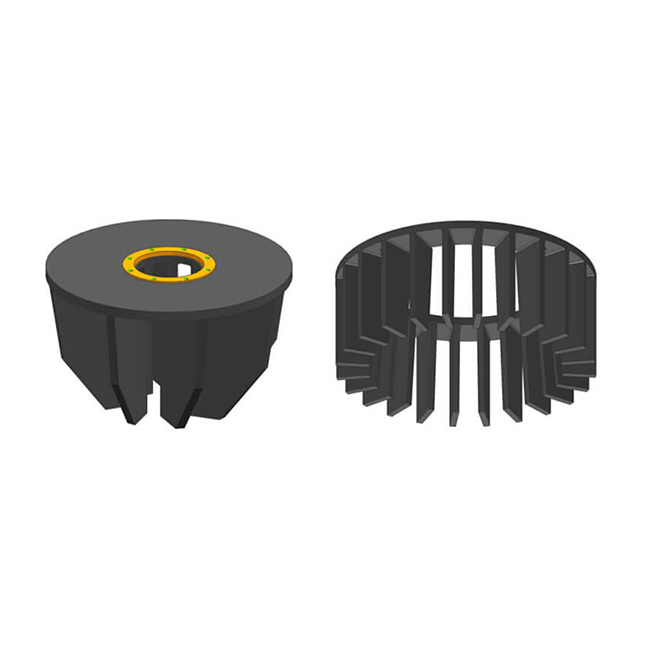

Open impellers, also known as top-feed impellers, are designed for “open-type” flotation machines. Their structure promotes vertical pulp circulation, which is vital for effective mineral separation.

Design Characteristics: These impellers feature a design that prevents solids from settling at the bottom of the flotation cell. This ensures a uniform upward current throughout the cell, which is critical for maintaining optimal flotation conditions.

Benefits:

● Preventing Settling: The open design helps keep materials in suspension, which is essential for efficient processing.

● Uniform Pulp Circulation: This promotes consistent contact between air bubbles and minerals, enhancing recovery rates.

Suitable Applications: Open impellers are particularly effective for handling coarser materials, making them ideal for operations dealing with rougher ores.

Brand Highlight: Strudex’s open impeller design has proven effective in various mining conditions, showcasing its reliability and performance in real-world applications.

Impeller Type | Key Advantages | Best Applications |

Receded Disk Impellers | High aeration, froth stability | Sulfide ore processing |

Conical Disk Impellers | Balanced agitation, versatile | General-purpose flotation |

Open (Top-Feed) Impellers | Prevents settling, uniform circulation | Coarse material handling |

These top three flotation impellers highlight the diversity of options available to mining operations. Each type offers unique advantages, making them suitable for different applications in mineral processing.

Selecting the right flotation impeller is crucial for optimizing mineral processing in mining. Several factors can influence your choice, including compatibility with flotation machines and material selection.

When choosing a flotation impeller, it's essential to ensure it matches your existing flotation equipment. Compatibility can significantly affect performance and efficiency.

Importance of Matching Impellers:

● Performance Optimization: A well-matched impeller can enhance the overall efficiency of the flotation process.

● Operational Reliability: Proper compatibility reduces the risk of mechanical failures and maintenance issues.

Popular Flotation Machine Models: Here’s a brief overview of some widely used flotation machine models that work well with top impellers:

Flotation Machine Model | Compatible Impellers | Key Features |

Metso Outotec OK 100 | Receded Disk, Conical Disk | High aeration and froth stability |

FLSmidth Dorr-Oliver | Conical Disk, Open Impeller | Versatile for various ore types |

Strudex SF Series | All three types | Broad compatibility and reliability |

Strudex Compatibility: Strudex impellers are designed to be compatible with major flotation machine brands. This broad compatibility ensures that you can easily integrate Strudex products into your existing systems, enhancing performance without the need for extensive modifications.

The material of the flotation impeller plays a significant role in its performance and durability. Common materials include rubber, polyurethane, and stainless steel, each offering distinct advantages.

Comparing Material Options:

● Rubber: Known for its excellent abrasion resistance, rubber impellers are ideal for less aggressive environments. They provide flexibility and are cost-effective.

● Polyurethane: This material offers superior chemical resistance and durability, making it suitable for harsh conditions. It is often preferred for corrosive slurry environments.

● Stainless Steel: While durable, stainless steel impellers are less common in standard applications due to their higher cost and weight.

Choosing the Right Material: When selecting a material, consider the type of ore and processing conditions. For example, abrasive ores may require rubber or polyurethane, while more stable conditions might allow for stainless steel options.

Strudex Material Options: Strudex offers both rubber and polyurethane impellers, providing flexibility based on your operational needs. The rubber impellers are designed for durability, while polyurethane options ensure high performance in aggressive chemical environments.

Material | Durability | Best Use Cases | Cost Effectiveness |

Rubber | High | Moderate abrasion applications | Cost-effective |

Polyurethane | Superior | Corrosive environments | Higher initial cost |

Stainless Steel | Moderate | Laboratory settings | Most expensive |

These considerations are vital when selecting a flotation impeller for your mining operations. By ensuring compatibility with your flotation machines and choosing the right material, you can enhance the efficiency and effectiveness of your mineral processing efforts.

Flotation impellers are essential for maximizing efficiency in mineral processing. Their performance advantages significantly impact both operational longevity and cost efficiency.

High-quality materials are crucial for the durability of flotation impellers. Impellers made from advanced materials like rubber and polyurethane are designed to withstand harsh conditions, ensuring they last longer and perform better.

Extended Service Life:

● Material Quality: Impellers crafted from high-grade materials resist wear and tear, extending their operational lifespan. This means fewer replacements and less downtime.

● Case Studies: For instance, a mining operation using Strudex impellers reported a 30% increase in service life compared to standard rubber impellers. This improvement translates to significant savings in maintenance costs and operational efficiency.

Strudex Performance Metrics: Strudex impellers are engineered for maximum durability. Data shows that their rubber impellers have an average service life of over 5,000 hours, while polyurethane options can exceed 7,000 hours in demanding conditions. This performance ensures consistent operation and reduces the frequency of replacements.

The total cost of ownership is a critical factor when selecting flotation impellers. Understanding maintenance needs and operational efficiency can lead to substantial savings.

Maintenance Needs:

● Lower Maintenance Frequency: High-quality impellers require less frequent maintenance, which minimizes downtime. This is particularly valuable in continuous mining operations.

● Cost Analysis: A study revealed that operations using Strudex impellers experienced a 20% reduction in maintenance costs over three years, thanks to their robust design and longevity.

Long-Term Savings: By investing in efficient flotation impellers, mining operations can achieve significant long-term savings. Reduced downtime and maintenance lead to increased productivity, allowing operations to run smoothly and profitably.

Strudex Cost Benefits: Strudex products are designed with cost efficiency in mind. Their impellers not only have a low total cost of ownership but also deliver outstanding performance, making them a smart choice for mining companies looking to optimize their operations.

Impeller Brand | Average Service Life | Maintenance Frequency | Estimated Cost Savings |

Strudex Rubber | 5,000 hours | Low | 20% over 3 years |

Strudex Polyurethane | 7,000 hours | Very Low | 25% over 3 years |

Standard Rubber | 3,500 hours | High | Baseline |

These performance advantages highlight the importance of selecting the right flotation impeller. By focusing on wear resistance and operational cost efficiency, mining operations can significantly enhance their productivity and profitability.

Choosing the right flotation impeller is crucial for mining operations.

The performance, durability, and compatibility of impellers directly impact efficiency.

Consider your operational needs when selecting an impeller.

Strudex products stand out as leaders in flotation impeller technology.

Their innovative designs enhance performance and reduce costs, making them a smart choice for any mining operation.

A: Common issues include wear and tear, improper aeration, and compatibility problems with flotation machines.

A: Replacement frequency varies, but high-quality impellers like Strudex can last over 5,000 hours.

A: Regular inspections, proper cleaning, and ensuring correct installation can enhance longevity.

A: Impellers improve slurry mixing and aeration, directly influencing mineral recovery rates.

A: Strudex impellers are known for their durability, efficiency, and broad compatibility with various flotation machines.