+86-173-0318-1768

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

Vertical roller mills (VRMs) are crucial in industries like cement, mining, and chemicals. Their energy efficiency and versatility make them the go-to choice for grinding various materials. But do you know what makes a VRM work so effectively?

In this article, we'll dive into the essential parts of a vertical roller mill. You'll learn how each component contributes to the mill's performance and efficiency. By the end, you'll have a clear understanding of how these components work together to ensure smooth operation and longevity of the mill.

Vertical roller mills are widely used in cement, mining, and chemical industries for their energy efficiency and ability to grind diverse materials.

Key components of VRMs include the grinding table, rollers, grinding table liners, and classifier, each playing a crucial role in the milling process.

Regular maintenance, including lubrication, inspection of wear-prone parts like rollers and table liners, and hardfacing techniques, is essential for maximizing mill lifespan.

The efficient drive system and hydraulic systems ensure stable and reliable operation, reducing downtime and improving overall efficiency.

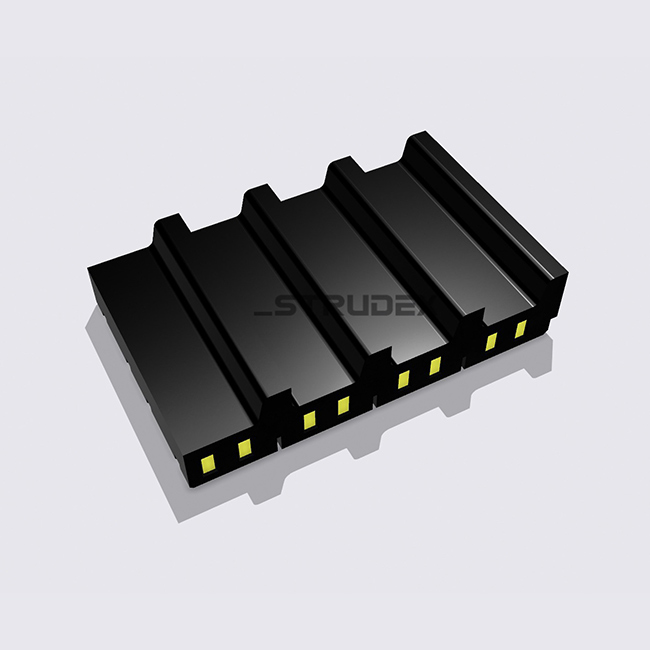

Companies like Strudex offer high-quality mill components and maintenance solutions, ensuring consistent performance and durability.

Vertical roller mills consist of various parts working together to grind materials efficiently. Here's a closer look at the key components.

| Component | Description | Key Characteristics | Function in Milling |

|---|---|---|---|

| Grinding Table | The foundation of the mill that supports the material and grinding forces. | Made from cast iron; segmented for stability. | Distributes material evenly across the mill for uniform grinding. |

Description:

The grinding table is the foundation of the vertical roller mill. It supports the weight of the material and the grinding force produced by the rollers.

Key Characteristics:

The grinding table is typically made from cast iron and consists of several segments bolted together to form a stable surface for material grinding.

Function in Milling:

The grinding table helps distribute the material evenly for grinding, ensuring a smooth and continuous operation. It plays a crucial role in maintaining a uniform material layer during the grinding process.

| Component | Description | Material & Design | Role in Operation |

|---|---|---|---|

| Rollers | The core component responsible for grinding material by rotating around the table. | Made from high-quality steel with wear-resistant coatings. | Apply pressure on material, grinding it into fine powder. |

Description:

Rollers are the heart of the vertical roller mill. They rotate around the grinding table, crushing and grinding the material into fine powder.

Material and Design:

Rollers are generally made from high-quality steel with wear-resistant coatings. This ensures their longevity and ability to withstand the high pressures they experience during the grinding process.

Role in Operation:

The rollers exert pressure on the material, causing it to be crushed and ground. They are designed to handle a variety of materials, from clinker to slag, efficiently.

| Component | Description | Material & Durability | Function in Milling |

|---|---|---|---|

| Grinding Table Liners | Protect the grinding table from abrasive forces and wear. | Made from wear-resistant materials like high-chromium cast iron or alloy steels. | Extend the life of the grinding table, ensuring consistent milling. |

Function:

The grinding table liners protect the grinding table from abrasive forces and wear. These parts play a critical role in maintaining the structural integrity of the grinding table.

Material and Durability:

Typically made from wear-resistant materials like high-chromium cast iron or alloy steels, these liners are bolted to the grinding table and ensure that it lasts longer.

Tip: Ensure that grinding table liners are regularly replaced to avoid excessive wear that could lead to more extensive repairs.

| Component | Description | Adjustability | Importance |

|---|---|---|---|

| Classifier | Separates fine particles from coarse ones during the milling process. | Rotor speed is adjustable to control particle size. | Ensures the desired particle size is achieved by adjusting the rotor speed. |

Description:

Located above the grinding table, the classifier separates fine particles from unground material. It ensures that only properly ground particles are removed from the mill, while coarse particles return for further grinding.

Adjustability:

The classifier's rotor speed can be adjusted to control the fineness of the particles produced by the mill.

Importance:

By regulating the size of particles, the classifier ensures that the desired product quality is consistently achieved, preventing over-grinding.

In addition to the primary grinding components, several supporting systems are essential to the mill's smooth operation.

| Component | Description | Function | Importance |

|---|---|---|---|

| Drive System | Powers the grinding table and rollers for smooth operation. | Includes motor, gearbox, and coupling. | Essential for the rotational movement of the grinding components. |

Description:

The drive system powers the vertical roller mill's grinding table and rollers. It typically includes a motor, a gearbox, and a coupling.

Function:

The motor provides the power, the gearbox reduces the speed of the motor to an appropriate level for grinding, and the coupling connects the two systems for smooth operation.

Types:

The drive system configuration can vary depending on the mill's size and energy requirements, with larger mills often requiring more robust drive mechanisms.

Function:

The hydraulic system controls the pressure applied by the grinding rollers. It maintains a constant force, ensuring optimal grinding efficiency.

Components:

The system includes hydraulic cylinders that control the vertical position of the rollers, adjusting the pressure applied during the grinding process.

| Component | Description | Role | Airflow Process |

|---|---|---|---|

| Hot Gas Ducting & Ventilation | Facilitates drying of materials during grinding. | Helps in drying materials, moving fine particles into the separator. | Air is drawn through the mill, drying the material while it is ground. |

Role:

The hot gas ducting and ventilation system assists in drying the material during the grinding process. Hot air is drawn through the mill, facilitating the drying of moist material as it is ground.

Airflow Process:

Air moves upward through the mill, carrying fine particles into the separator. This airflow helps in the simultaneous drying and grinding of materials.

Beyond the primary components, several smaller yet equally important parts are vital to the mill’s functionality.

| Component | Description | Role | Importance |

|---|---|---|---|

| Bearings & Seals | Support the rotation of the rollers and grinding table. | Ensure smooth rotation and prevent material leakage. | Essential for minimizing friction, wear, and extending equipment life. |

Role:

Bearings support the rotation of the rollers and the grinding table. Seals prevent the leakage of materials and ensure the mill operates in a clean, controlled environment.

Importance:

Both bearings and seals play a crucial role in minimizing friction and wear, ensuring the longevity of the mill.

Purpose:

The lubrication system helps reduce friction between moving parts, such as the grinding rollers, table, and gears. Proper lubrication ensures smooth operation and extends the life of the components.

Types:

Oil-based lubrication systems are commonly used to lubricate bearings, rollers, and gears. Ensuring proper oil quality and levels is essential for maintaining the efficiency of the lubrication system.

Importance:

Dust collection systems capture airborne particles generated during milling. This is essential for maintaining a clean environment and complying with environmental regulations.

Components:

Typically, a bag filter or electrostatic precipitator is used to collect and remove dust from the air, preventing contamination and health risks.

Maintaining a vertical roller mill properly is essential for its long-term performance. Regular inspections and timely maintenance can prevent unexpected breakdowns.

Grinding Rollers and Table Liners:

These parts are subjected to intense wear due to constant friction and pressure. Regular inspection is required to check for signs of damage and ensure optimal performance.

Tips for Maintaining Parts:

Applying hardfacing techniques to rollers and liners can significantly extend their lifespan, minimizing downtime and reducing overall maintenance costs.

Lubrication:

Lubricate bearings and rollers regularly to reduce friction and wear.

Inspection:

Inspect grinding rollers, table liners, and other components for wear. Ensure the classifier blades are properly aligned.

Implementing a proactive maintenance schedule can prevent equipment failure and ensure consistent mill performance.

Signs for Replacement:

Unusual vibrations, increased energy consumption, and irregular particle size are common signs that parts need replacing.

Cost-Effective Repair:

Hardfacing and timely component replacement help extend the life of critical parts and reduce downtime.

Understanding the components of a vertical roller mill is crucial for maximizing performance and reducing downtime. By maintaining key parts like grinding rollers, table liners, and the hydraulic system, operators can ensure smooth operation for years. Regular inspections and proper maintenance practices are vital to prolonging the mill's lifespan. Operators should prioritize timely maintenance and component replacement to keep the mill running efficiently and reliably.

Strudex offers top-quality mill components, including grinding rollers, table liners, and hydraulic systems. By choosing Strudex, companies can enhance their mill's performance with durable, wear-resistant parts, ensuring long-term reliability and efficiency.

A: A Vertical Roller Mill (VRM) is a grinding machine used in various industries like cement and mining. It uses rollers and a rotating table to grind materials into fine powder efficiently.

A: The main components include the grinding table, rollers, grinding table liners, classifier, hydraulic system, and drive system, each contributing to the grinding process.

A: Mill liners protect the grinding table from abrasive forces. Made from wear-resistant materials, they help extend the life of the grinding table and improve grinding efficiency.

A: Regular maintenance of key components like rollers and liners ensures smooth operation, reduces downtime, and extends the lifespan of the mill.

A: Regular inspections should be conducted, especially on wear-prone parts like grinding rollers and table liners, to ensure optimal performance and prevent breakdowns.