+86-173-0318-1768

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

Have you ever wondered how valuable minerals are separated from waste? The flotation impeller plays a crucial role in this process.

In this article, we will explore what a flotation impeller is and its significance in mineral processing.

You’ll learn how these components enhance efficiency and effectiveness in mining operations.

A flotation impeller is a vital component of flotation machines used in mineral processing. Its primary function is to agitate the slurry, which is a mixture of water and crushed ore. By doing this, it helps introduce air into the mixture, forming bubbles that facilitate mineral separation.

In essence, the flotation impeller creates a dynamic environment where valuable minerals can attach to the bubbles, allowing them to rise to the surface for collection. This process is crucial in extracting metals like copper, lead, and zinc from their ores.

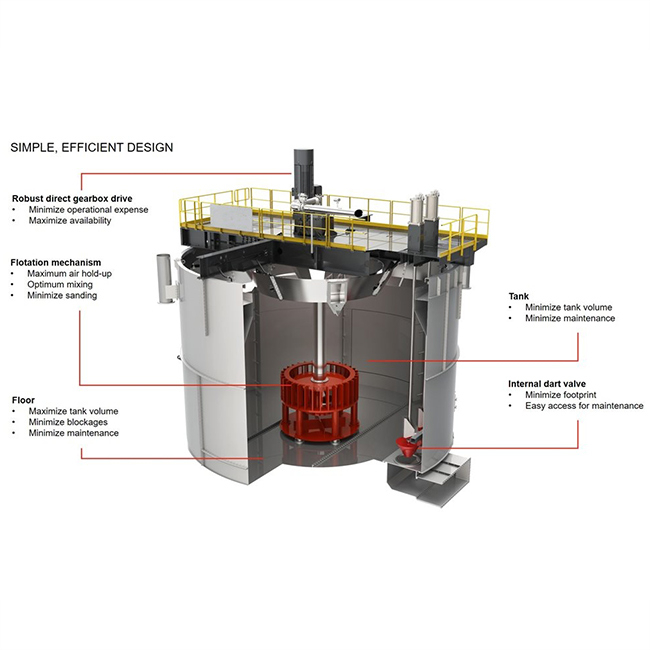

Flotation machines are specialized equipment designed to separate minerals based on their surface properties. They consist of several key components, including:

● Impellers: These rotate to agitate the slurry and introduce air.

● Stators: Stationary parts that help direct the flow of the slurry.

● Aeration Systems: Devices that inject air into the slurry.

Here’s a simple diagram illustrating the main components of a flotation machine:

+-------------------+

| Flotation Tank |

| |

| +-----------+ |

| | Stator | |

| +-----------+ |

| | |

| +-----------+ |

| | Impeller | |

| +-----------+ |

| | |

| Aeration System |

+-------------------+

These machines operate by creating a froth layer at the top, where the mineral-laden bubbles accumulate. The design of the flotation machine is essential for optimizing performance and ensuring effective mineral recovery.

Flotation impellers are not just components; they significantly impact the entire mineral separation process. Their role is crucial for several reasons:

1. Significance in Mineral Separation: The impeller's ability to create bubbles and keep particles suspended ensures that valuable minerals do not settle at the bottom. This action prevents "sanding," a condition where heavy particles accumulate, hindering the separation process.

2. Contribution to Efficiency and Effectiveness in Beneficiation: The efficiency of a flotation operation largely depends on the impeller's design and functionality. Impellers like those produced by Strudex are engineered to maximize air hold-up and optimize pulp mixing. This means that more minerals can be extracted in less time, enhancing overall productivity.

Here’s a table summarizing the key benefits of using high-quality flotation impellers:

Benefit | Description |

Enhanced Recovery Rates | Improved separation efficiency leads to higher yields. |

Reduced Maintenance Costs | Durable materials increase lifespan and decrease downtime. |

Optimized Energy Efficiency | Efficient designs lower energy consumption during operation. |

By understanding the purpose and functions of flotation impellers, we can appreciate their critical role in modern mining operations. The advancements in impeller technology continue to drive improvements in mineral processing, making it more efficient and sustainable.

Strudex is a leading manufacturer in the mining and mineral processing sector, known for its innovative flotation impellers. The company originated as Huanyou Rubber Products, focusing on rubber manufacturing. Over the years, it has evolved into a specialized provider of high-performance components for flotation machines.

Strudex has built a strong reputation for quality and reliability. Their commitment to excellence is evident in their state-of-the-art production facilities and advanced engineering processes. The company serves a global market, supplying flotation impellers to various mining operations, enhancing mineral recovery worldwide.

At the heart of Strudex's offerings are its flotation impellers. These components are designed to maximize efficiency in mineral separation processes. Strudex impellers are crafted using advanced materials, ensuring durability and optimal performance under harsh conditions.

● Key Features of Strudex Flotation Impellers:

○ Enhanced aeration capabilities

○ Superior wear resistance

○ Customizable designs for various applications

Here’s a table highlighting the unique features of Strudex flotation impellers:

Feature | Description |

Aeration Performance | Optimized for fine bubble generation, improving recovery. |

Material Quality | Made from high-grade rubber and reinforced materials for longevity. |

Customization Options | Tailored designs to fit specific flotation machine models. |

Strudex places a strong emphasis on research and development. The company invests significantly in innovative technologies to enhance its product line. This commitment allows them to stay ahead of industry trends and meet the evolving needs of their customers.

Their production process is characterized by precision engineering and strict quality control. Each flotation impeller undergoes rigorous testing to ensure it meets high performance standards. This focus on quality not only boosts customer satisfaction but also reduces operational costs for mining companies.

In addition to flotation impellers, Strudex also produces a range of rubber wear-resistant products. These components are essential in various industrial applications, providing solutions that extend equipment life and reduce maintenance needs.

By combining advanced technology with a deep understanding of the mining industry, Strudex continues to be a trusted partner for companies seeking to improve their mineral processing operations.

A flotation impeller is the heart of the flotation process. It consists of a rotating component that plays a crucial role in mixing the slurry, which is a combination of water and finely crushed ore. As the impeller spins, it creates a vortex that draws the slurry into the center, agitating it effectively. This agitation is essential for ensuring that air is introduced into the mixture, forming bubbles that can capture valuable minerals.

The impeller's design influences its performance. The shape and speed determine how well it can mix and aerate the slurry. A well-designed impeller will maximize the introduction of air, enhancing the overall efficiency of the flotation process.

One of the primary functions of a flotation impeller is to disperse air into the slurry. Fine bubbles are created as air is introduced, and their size is critical for effective mineral separation. Smaller bubbles have a higher surface area-to-volume ratio, which allows them to attach to mineral particles more effectively.

Types of Aeration:

● Self-aspirated Systems: These rely on the impeller's rotation to draw air into the slurry.

● Forced-air Systems: These use external compressors to inject air directly into the flotation cell.

Here’s a table showing the differences between the two systems:

Feature | Self-Aspirated Systems | Forced-Air Systems |

Air Source | Generated by the impeller | External compressor |

Bubble Size | Generally larger | Typically smaller |

Energy Consumption | Lower | Higher |

Agitation is vital for keeping particles suspended in the slurry. The impeller's action prevents sedimentation, which is the settling of heavier particles at the bottom. This is crucial for maintaining a consistent flow of material through the flotation process.

Micro-turbulence created by the impeller enhances the collision between bubbles and particles. This interaction is essential for the mineralization process, where bubbles attach to the desired minerals, allowing them to float to the surface.

Chemical reagents play a significant role in flotation, and the impeller ensures they are evenly distributed throughout the slurry. These reagents help modify the surface properties of the minerals, making them more or less hydrophobic.

Effective mixing of reagents is necessary for optimal performance. When they are uniformly distributed, it increases the chances of successful bubble-particle attachment.

In summary, the flotation impeller is a complex yet efficient device that facilitates the critical processes of air dispersion, particle suspension, and reagent mixing. Its design and functionality are key to maximizing mineral recovery in flotation operations.

Flotation impellers come in various models, each designed for specific applications in mineral processing. Some popular models include:

● A-series: Known for its robust design, suitable for a wide range of ores.

● SF-series: This model excels in self-aspirating flotation, ideal for fine particle recovery.

● BF-series: Features a unique design that enhances bubble formation and mineral recovery.

● KYF-series: A versatile option that combines high efficiency with ease of operation.

● XCF-series: Designed for forced-air systems, optimizing air dispersion.

● JJF-series: Offers high mixing efficiency and is often used in large-scale operations.

● BSK-series: Known for its durability and effectiveness in harsh environments.

Each of these models has variations in design, allowing them to cater to different types of ores and processing conditions. The choice of impeller model can significantly impact mineral recovery rates and operational efficiency.

Here’s a table summarizing the key features of these models:

Model | Key Features | Best Suited For |

A-series | Robust design | Various ore types |

SF-series | Self-aspirating, fine recovery | Fine particle flotation |

BF-series | Enhanced bubble formation | High mineral recovery |

KYF-series | Versatile, efficient | General flotation operations |

XCF-series | Forced-air optimization | Air dispersion |

JJF-series | High mixing efficiency | Large-scale operations |

BSK-series | Durable for harsh conditions | Tough mining environments |

The materials used in constructing flotation impellers play a crucial role in their performance and longevity. Traditionally, metals were the primary choice for impellers, but modern materials have changed the landscape.

● Rubber vs. Polyurethane: Rubber impellers are known for their flexibility and resistance to wear, while polyurethane offers superior durability and chemical resistance. The choice between these materials often depends on the specific requirements of the flotation process.

● Advantages of Modern Materials: Modern materials like polyurethane provide significant advantages over traditional metals. They are lighter, which can improve the overall efficiency of the flotation machine. Additionally, they resist corrosion and wear better, leading to longer service life and reduced maintenance costs.

● Integration of Metal Skeletons: To enhance structural rigidity, many modern impellers incorporate metal skeletons. This integration allows for the benefits of lightweight materials while maintaining strength and durability. The result is an impeller that can withstand the rigors of mineral processing without compromising performance.

Here’s a comparison table of materials commonly used in flotation impellers:

Material | Advantages | Disadvantages |

Rubber | Flexible, wear-resistant | Limited chemical resistance |

Polyurethane | Durable, high chemical resistance | Can be more expensive |

Metal | Strong, long-lasting | Heavy, prone to corrosion |

Composite | Lightweight, combines benefits of both | May require careful handling |

Understanding the types of flotation impellers and the materials used in their construction helps in selecting the right equipment for specific mineral processing needs. Each model and material choice can significantly influence the efficiency and effectiveness of flotation operations.

Flotation impellers play a critical role in improving the efficiency of mineral separation processes. By effectively agitating the slurry and introducing air bubbles, these impellers enhance the attachment of valuable minerals to the bubbles, allowing them to rise to the surface for collection. This process significantly boosts mineral recovery rates.

For instance, Strudex flotation impellers have been shown to improve recovery rates in various mining operations. In one case study, a copper mining facility reported a 15% increase in recovery rates after switching to Strudex impellers. This improvement was attributed to the superior design and aeration capabilities of their products.

Here’s a table highlighting the impact of Strudex products on mineral recovery:

Case Study | Previous Recovery Rate | New Recovery Rate | Improvement (%) |

Copper Mine A | 70% | 85% | 15% |

Gold Mine B | 65% | 78% | 20% |

Zinc Mine C | 60% | 72% | 20% |

The longevity and wear resistance of modern flotation impellers are key factors in reducing operational costs. Strudex impellers are designed to withstand harsh conditions, which minimizes wear and extends their service life. This durability translates into fewer replacements and less downtime for maintenance.

Moreover, the reduced maintenance frequency associated with high-quality impellers leads to significant cost savings. Mining companies can allocate resources more efficiently, focusing on production rather than repairs. Strudex's annual production capacity allows them to meet demand while maintaining cost-effectiveness, ensuring that customers receive reliable products without excessive expense.

Here’s a quick overview of how Strudex impellers contribute to cost savings:

Benefit | Description |

Longevity | Extended service life reduces replacement costs. |

Reduced Maintenance | Fewer breakdowns lead to lower maintenance costs. |

Cost-Effectiveness | High production capacity meets market demands. |

The design features of flotation impellers also play a significant role in lowering energy consumption. Strudex impellers are engineered to optimize airflow and minimize turbulence, which reduces the energy required for flotation processes. This efficiency not only lowers operational costs but also contributes to a more sustainable mining practice.

The overall economic benefits for mineral processing operations are considerable. By using energy-efficient flotation impellers, companies can decrease their energy bills while enhancing productivity. This dual benefit makes Strudex products an attractive option for mining operations looking to improve their bottom line.

In conclusion, the advantages of using flotation impellers, particularly those from Strudex, are clear. They enhance mineral recovery, reduce operational costs, and boost energy efficiency, making them essential components in modern mineral processing.

Flotation impellers are vital in mineral processing. They enhance mineral recovery by improving separation efficiency. Key points include their various models, materials, and benefits like reduced operational costs.

Modern impellers, such as those from Strudex, offer longevity and energy efficiency. Overall, flotation impellers significantly impact mineral processing, making them essential for successful mining operations.

A: The main components include flotation impellers, stators, air supply systems, and the flotation cell itself.

A: Impellers agitate the slurry and introduce air, while stators help stabilize the flow and enhance bubble formation.

A: Yes, flotation impellers can be tailored in design and materials to meet specific mineral processing needs.

A: Regular inspections, cleaning, and timely replacement of worn parts are essential for optimal performance.

A: They improve mineral recovery rates, reducing waste and energy consumption, thus minimizing the environmental impact of mining.